| Drill rig Type |

Truck mounted, Hydraulically operated Drill rigs -With hands-free Auto rod loader system |

| Application |

Waterwell |

| Method of Drilling |

DTH Drilling |

| Drilling Capacity |

Hole size (DTH) - 6.5" to 14" diameter |

| standard Drilling Depth - 1500 feet (450 M) @ 6.5" diameter |

| Soil Formation usage |

Soft Hard |

| Chassis Structure |

Made with High-quality steel sections with Strong welded construction |

| Mast Assembly |

Heavy duty structural steel construction |

| Mast assembly operated by Hydraulic cylinder with pulley and wire rope |

| Drill pipe length : 20 feet (6 M) |

| Feed system |

Pullback : 15500 kgf @ 210 bar |

| Pulldown : 8600 kgf @ 210 bar |

| Fast feed up : 35 m/min |

| Fast feed down : 55 m/min |

| Reeving ratio : 1:3 |

| Hydraulic feed system : Double acting cylinder |

| Rotary head |

Single hydraulic motor driven spur gear reduction gearbox made with high-grade steel housing |

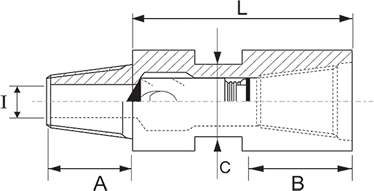

| Gear box type: oil lubrication type with top air entry and spindle thread connection in ID |

| Rotary head torque : 4500 N-m |

| Rotary head RPM: 0-100 RPM |

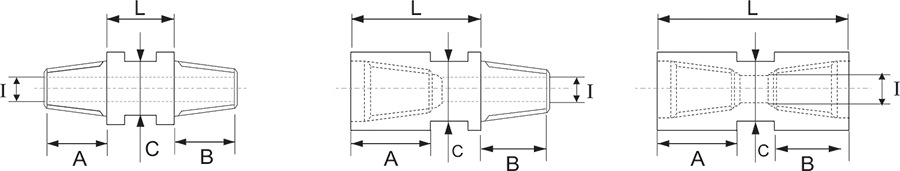

| Spindle ID Thread Size : 2-7/8” API IF Female Threads |

| Swivel working pressure : 350 PSI (24.1 bar) |

| Head travel : 20 feet |

| Hydraulics |

Prime Mover : Hydraulic system is driven by PTO of Truck |

| Hydraulic tank capacity : 800 Litres |

| Maximum Hydraulic system Pressure: 210 Bar |

| Hydraulic Oil cooler – 120 Gpm |

| Hydraulic pump : Two High Pressure pumps & Two Fixed Displacement |

| Double vane pumps directly coupled with 4-pod gearbox driven by truck PTO |

| Controls |

Compact control console - grouping the controls within easy reach of the operator |

| Hydraulic levelling Jacks |

Four hydraulic levelling jacks are provided with safety check valves |

| Break out clamps |

Breakout Clamps come with a top hydraulic breakout cylinder, a set of jaws and a bottom set of fixed grip jaws |

| Auto rod loader systems |

Lifting capacity upto 200 kgs. with 2 grippers and can handle up to 20 feet drill pipe with 0-90° swing |

| Water injection pump |

Triplex pump is driven by a hydraulic system with necessary control valves and suction filter. |

| Winch on Mast assembly |

2 Tonne - Swing Type |

| Airline Lubricator |

18 Litre oil tank with inline lubricator |

| Optional attachments* |

GPS monitoring system, night lights, Tools with tool box, Auto drilling, Digital display in control board, Welding generator, Mud pump and Hydraulic operate hammer opener |